Uncategorized

We finally received our long awaited shipment of full transparent, black, smoked clear and white shells to put cassette production into full swing next week. Next on order by popular demand will be colored shells such as red, green, yellow,…

Uncategorized

Have we got something cool for you guys… We have so many requests for picture discs lately but PDs have always been slow, expensive, unreliable plus they don’t always sound so great. Very soon we will be offering these new…

Uncategorized

We have taken on board client feedback and made some behind-the-scenes bug fixes and improvements to the online uploader. – more browsers are supported including many mobile devices – uploader client will now attempt to open up to 3 connections…

Vinyl Mastering

When you place an order with Mobineko there is a cutting questionnaire in the second step after quoting. Although it’s tempting to gloss over these details when ordering it’s super important that we understand each customer’s intent for every single…

Uncategorized

Some more cassette equipment just landed at Mobineko HQ. We have been working on reverse engineering the Otari DP-8, DP4050 and digital master reproducers to develop a high quality short run tape duplication system. The idea is to connect a…

Uncategorized

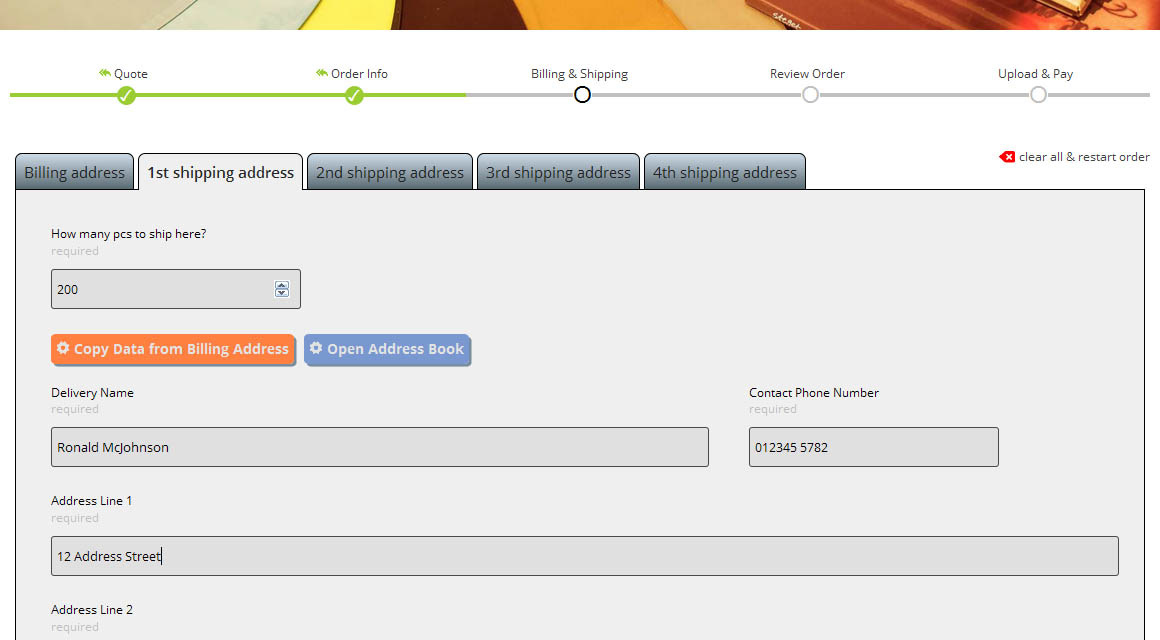

As promised we have finished the last stage of our new online apps with a brand new online ordering system. Once the updates are rolled out you will be able to proceed from the online quote section and order directly…

Uncategorized

Cassettes have always been something we’re interested in at Mobineko even though it’s a pretty small market. It’s recently come to our attention that most of the serious cassette duplicators and printers in Europe have shut up shop so the…

Uncategorized

So you’ve chosen your format, finished your artwork, tweaked it another ten times, got everything signed off with the artists.. and now there’s another choice to make?! It can be hard to decide which stock and coating to choose for…

FAQVinyl Mastering

2014/11/09 UPDATE! We now have a fancy new online app that will tell you how your record will likely sound at any given length, and also recommend what speed to cut at. Check it out here! A common question we…